PROCESS

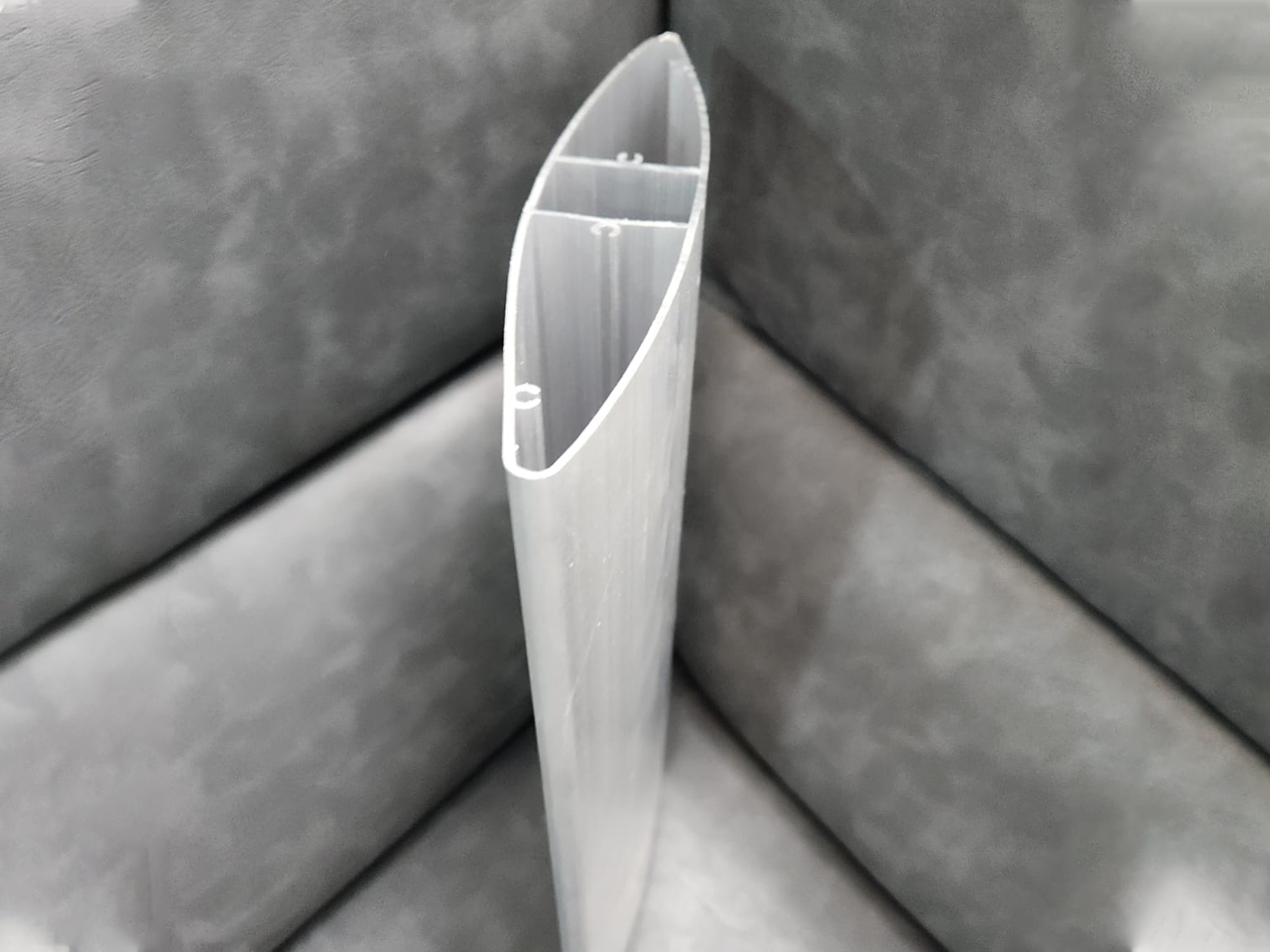

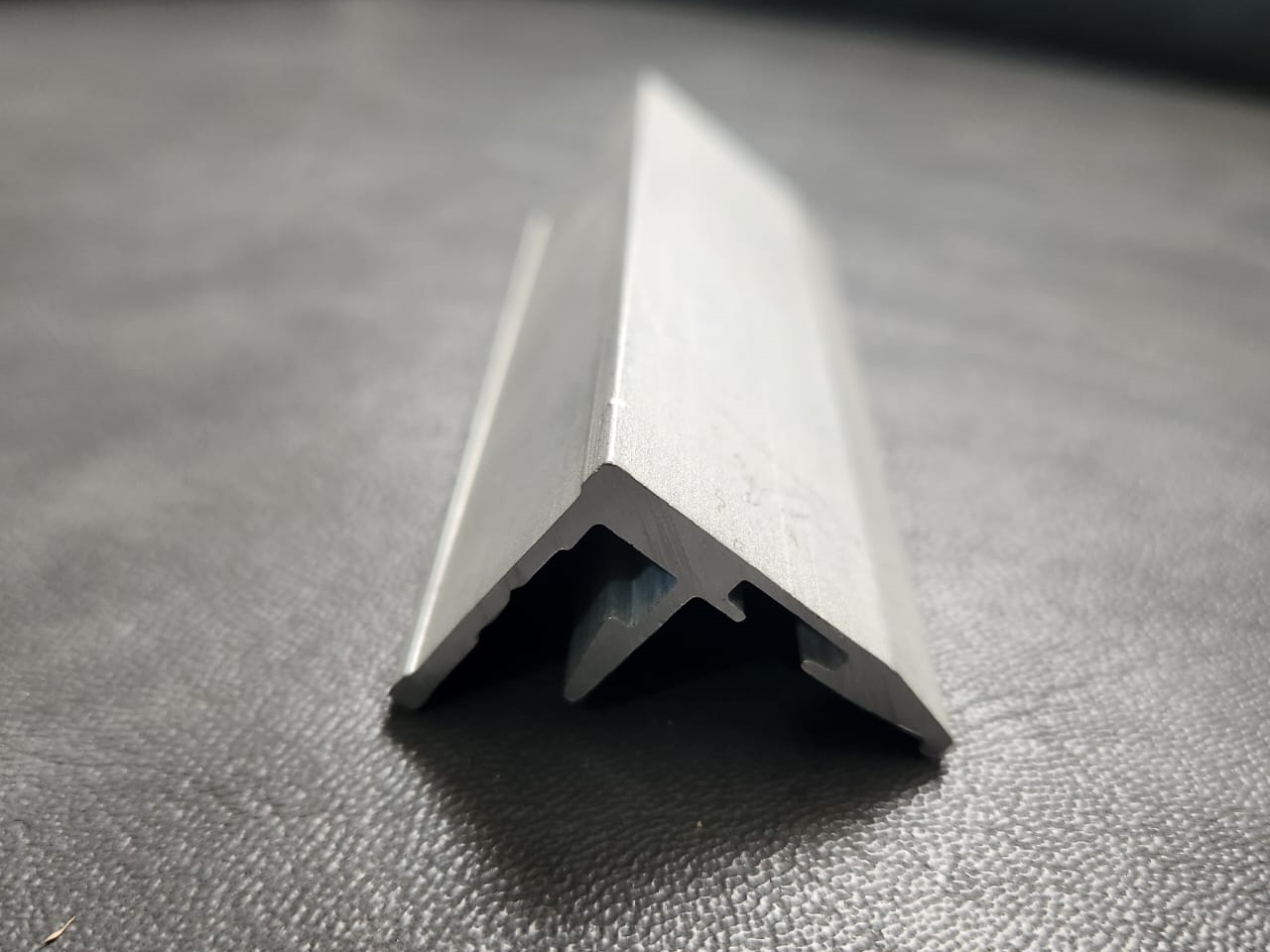

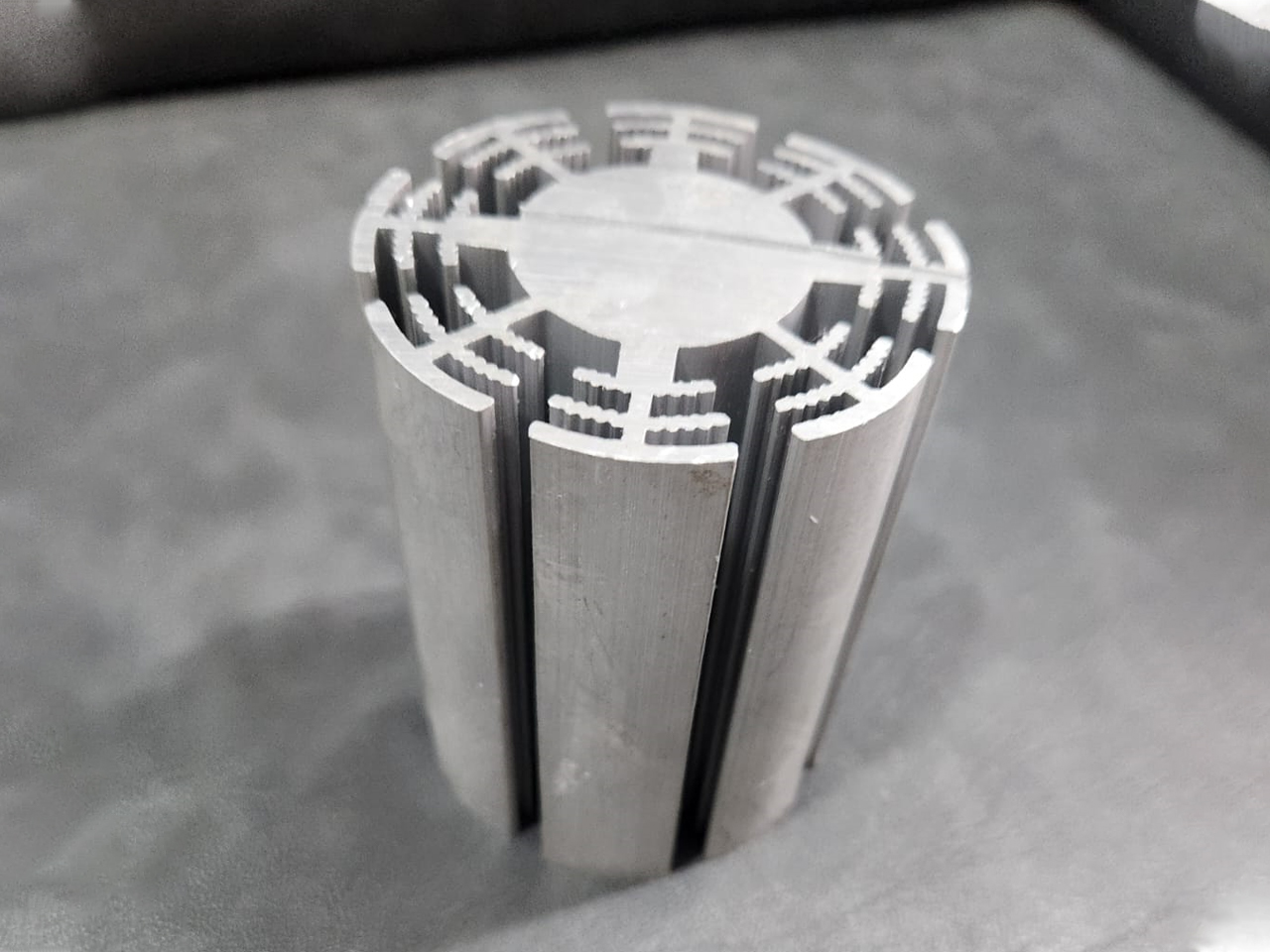

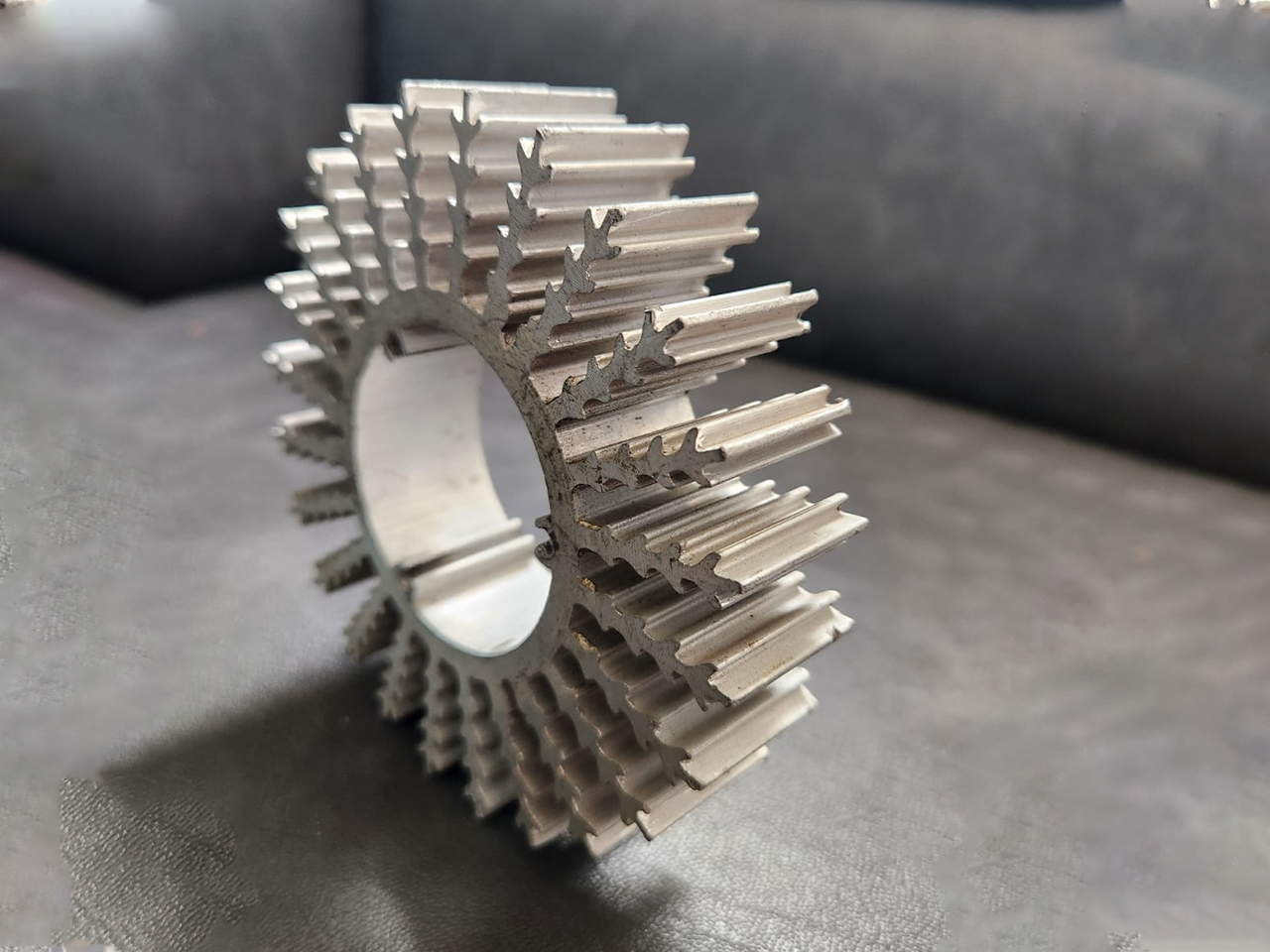

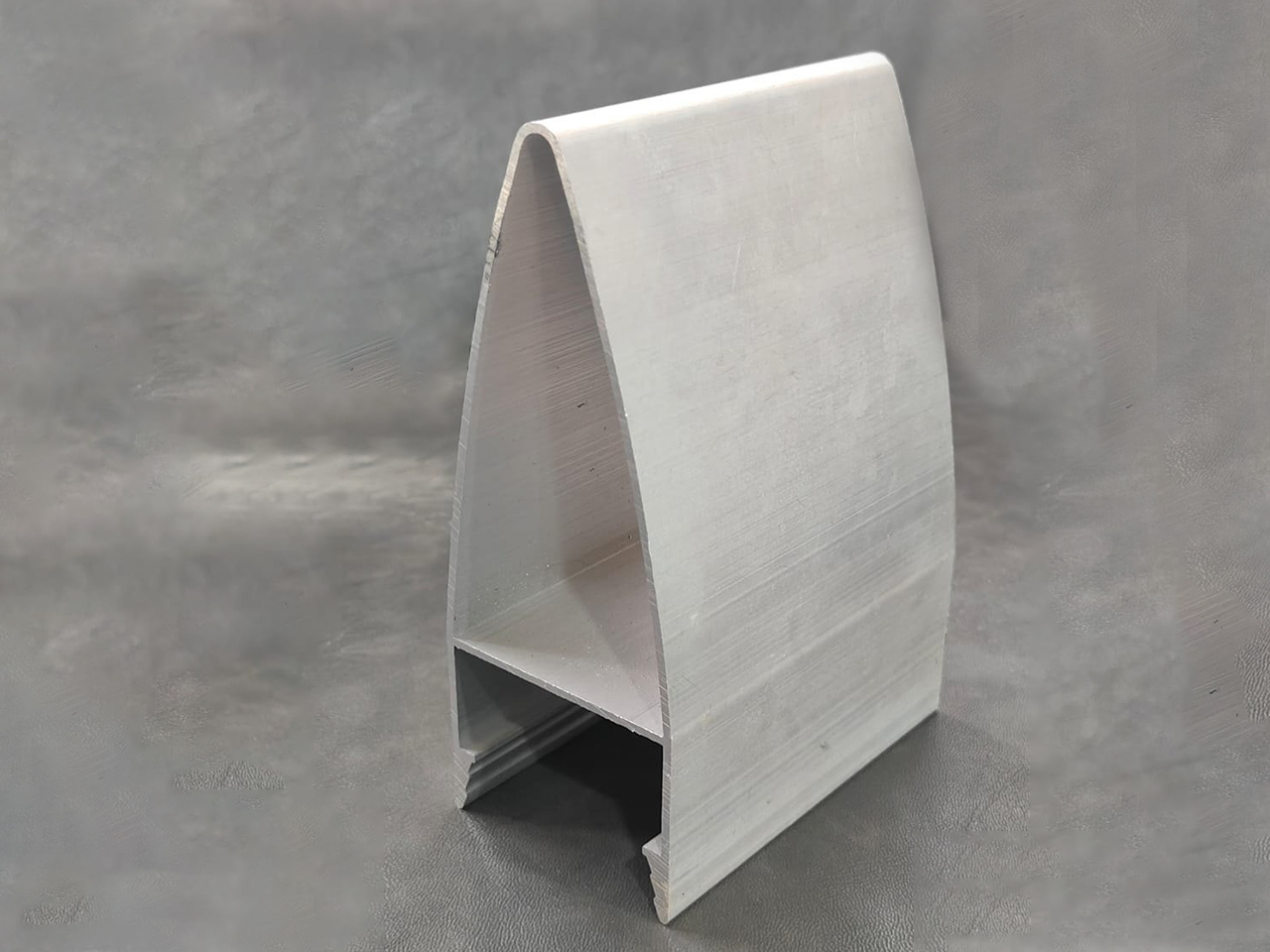

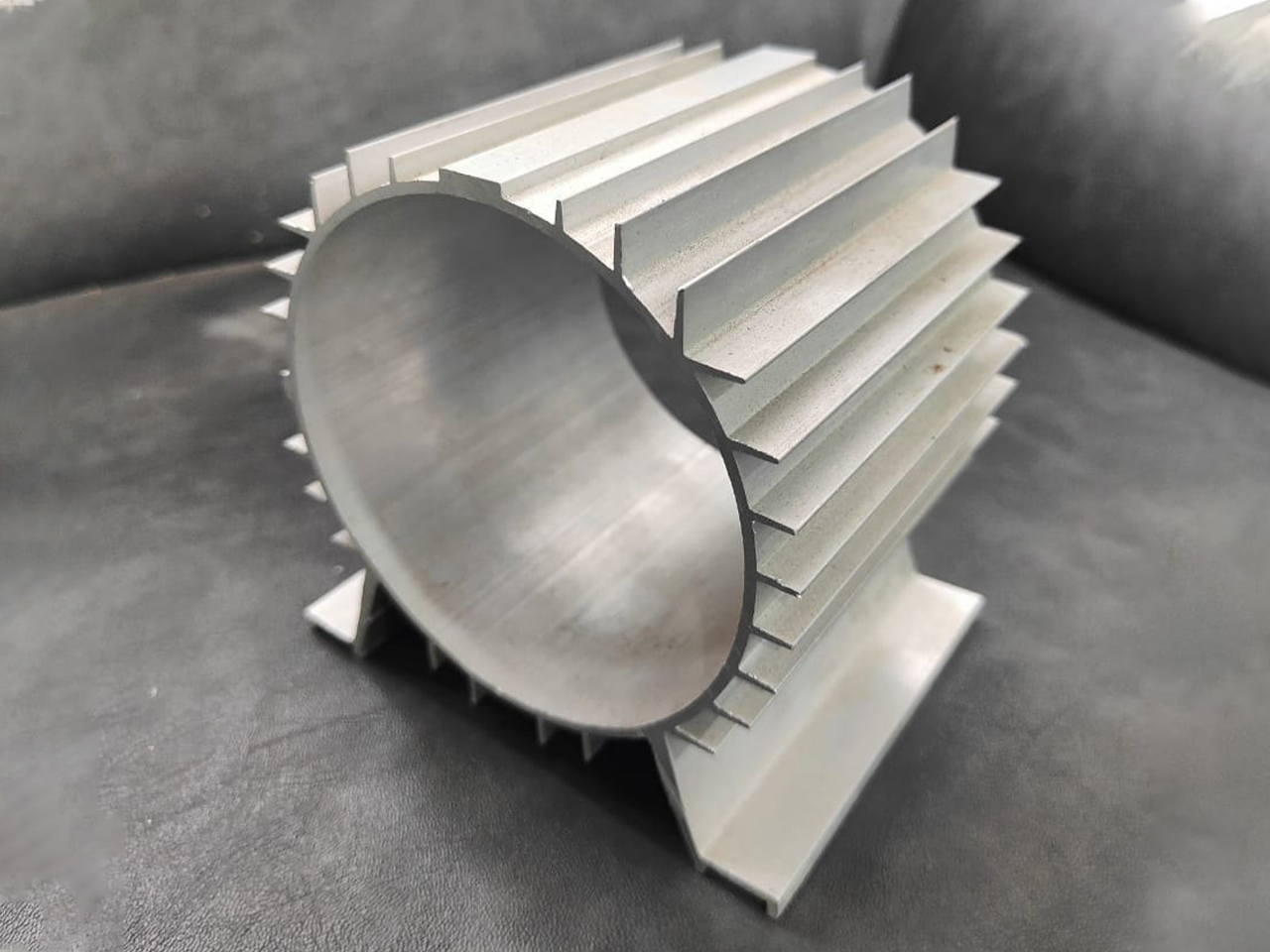

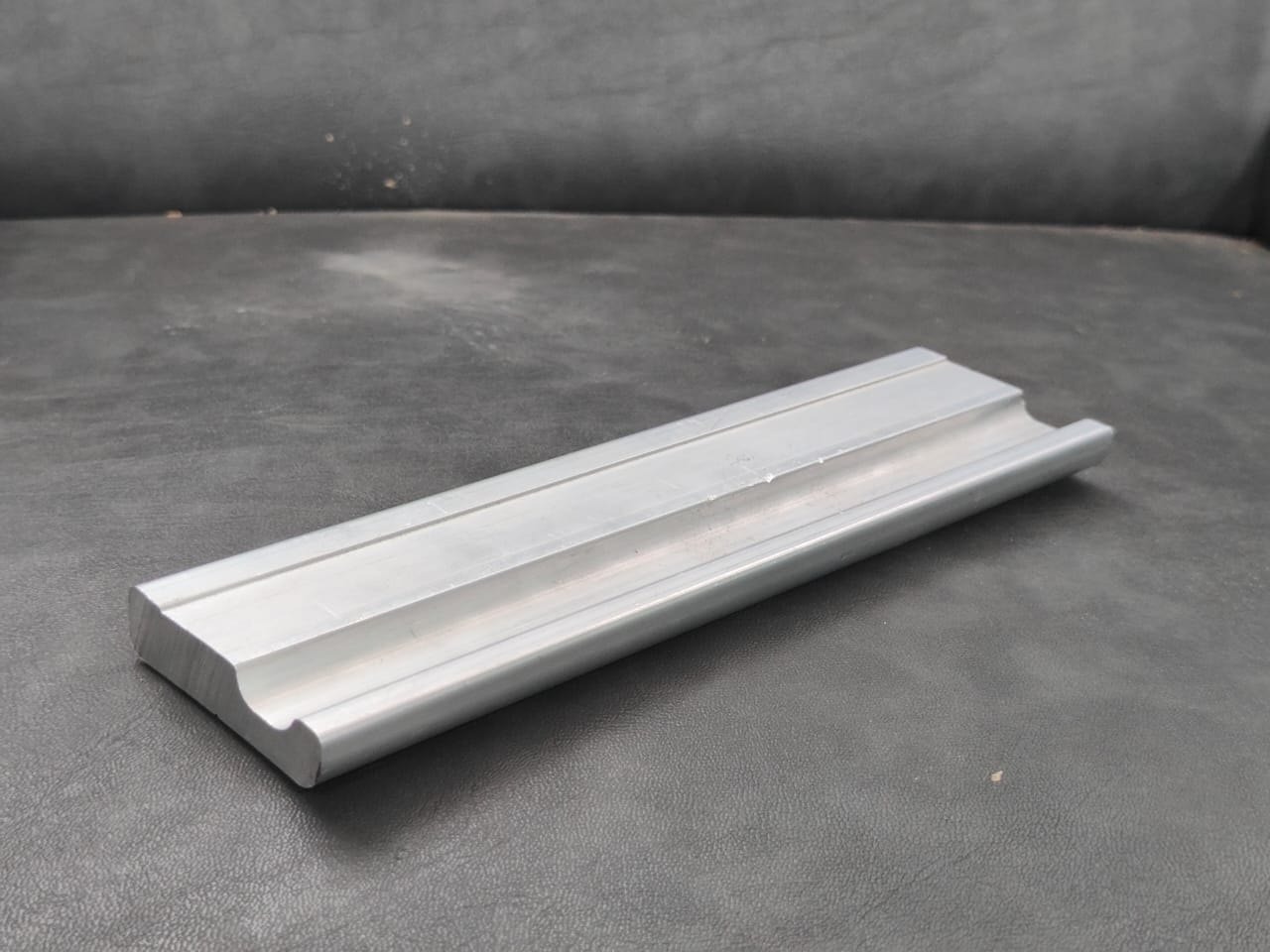

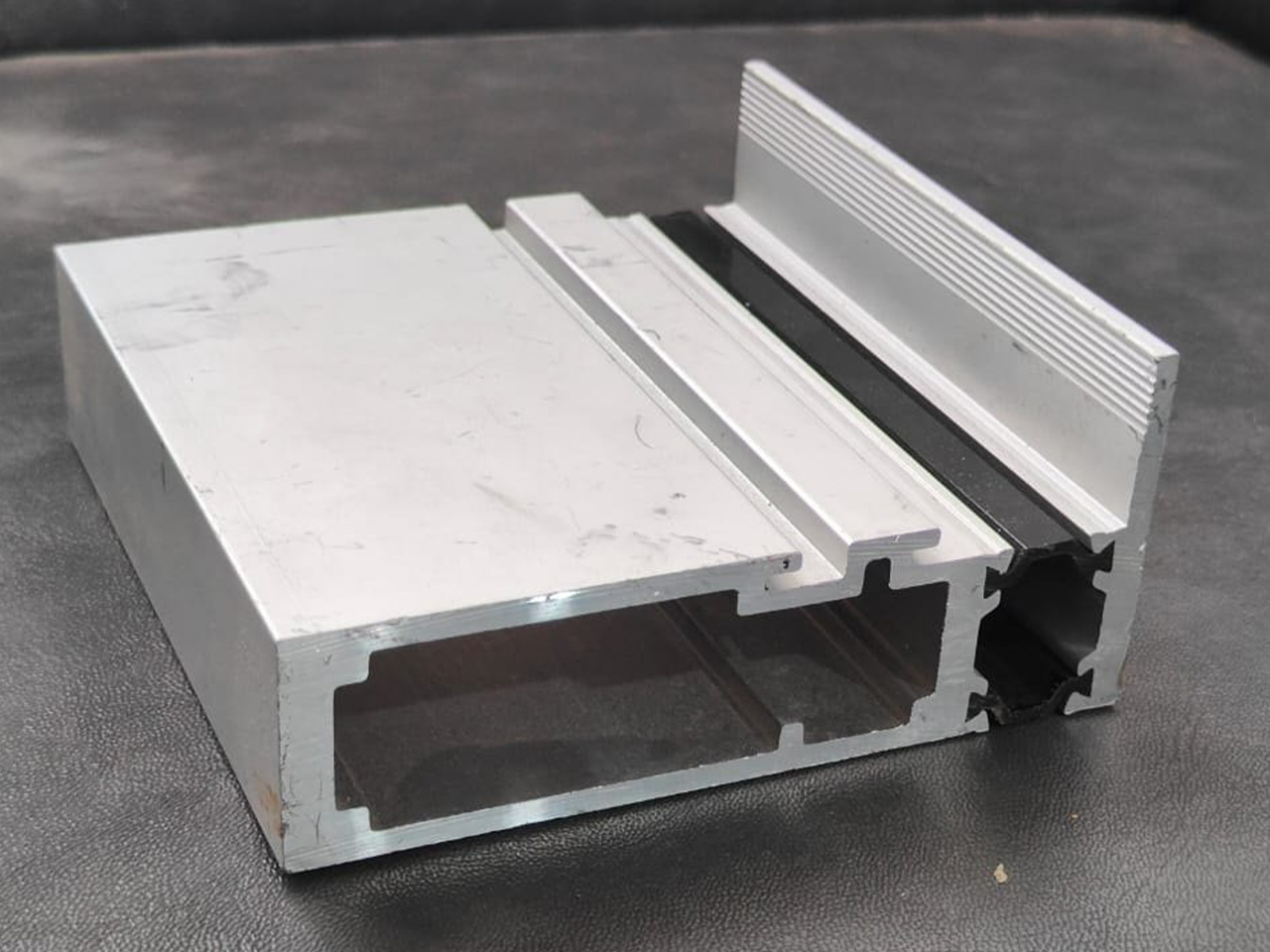

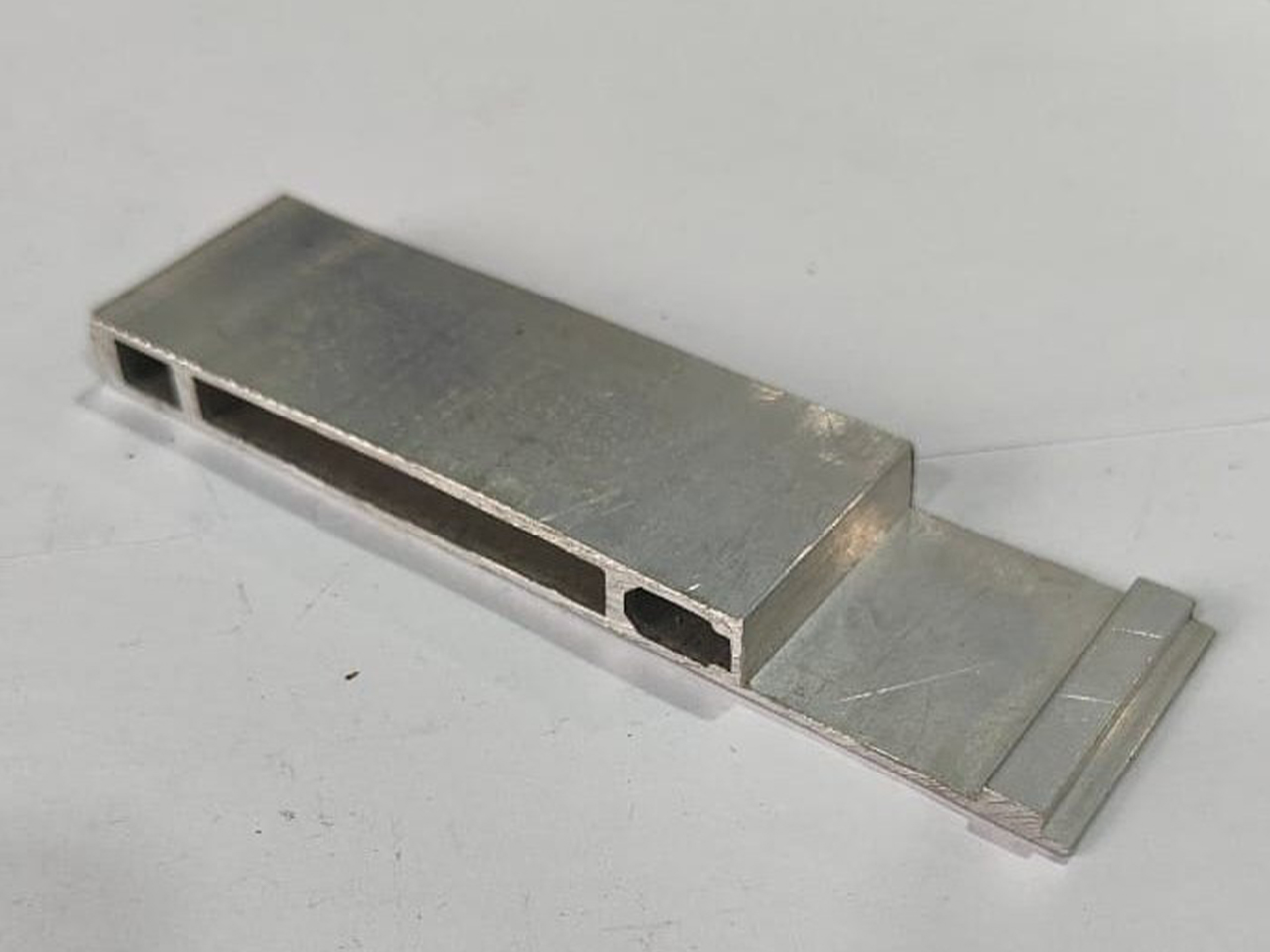

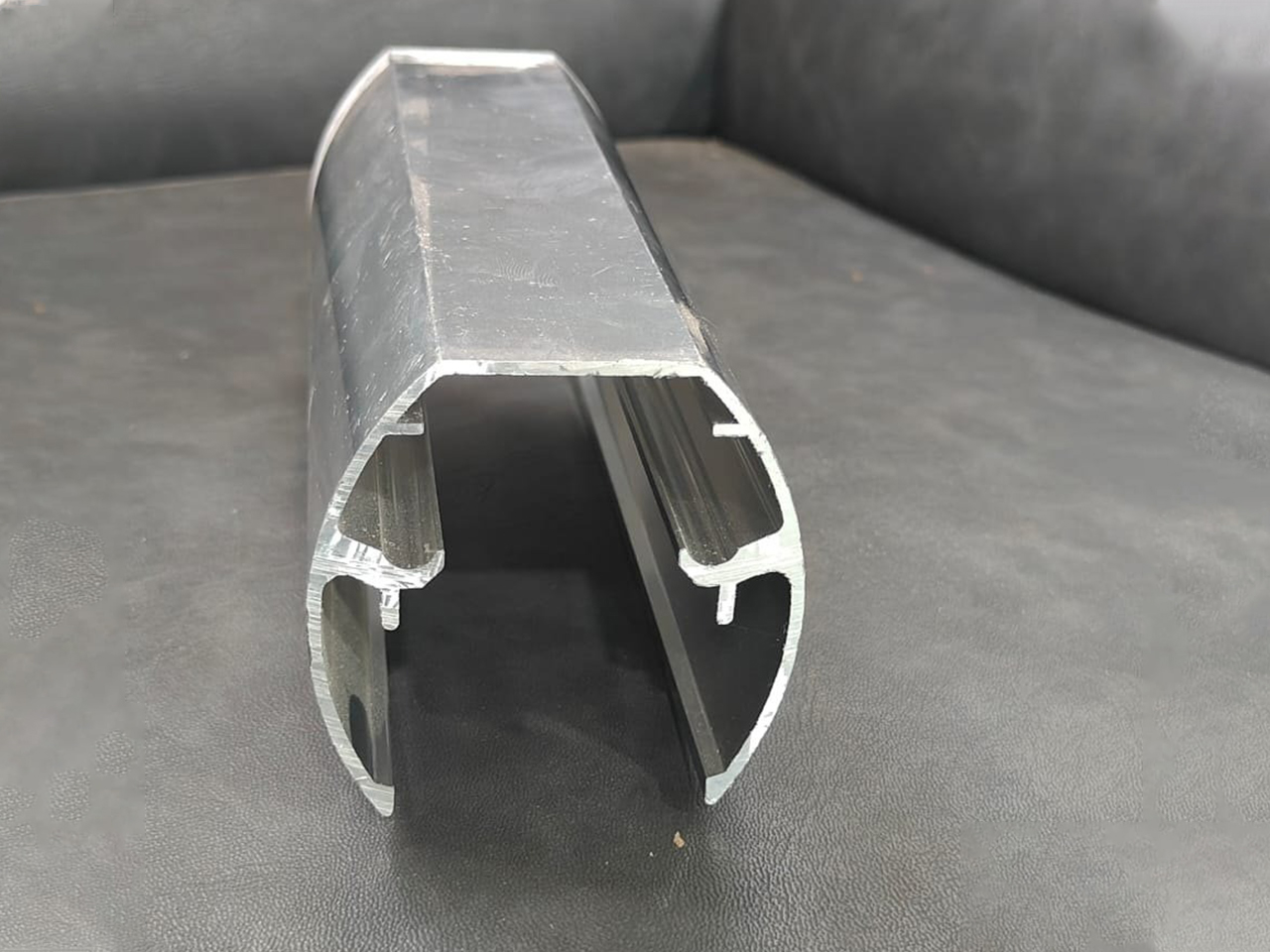

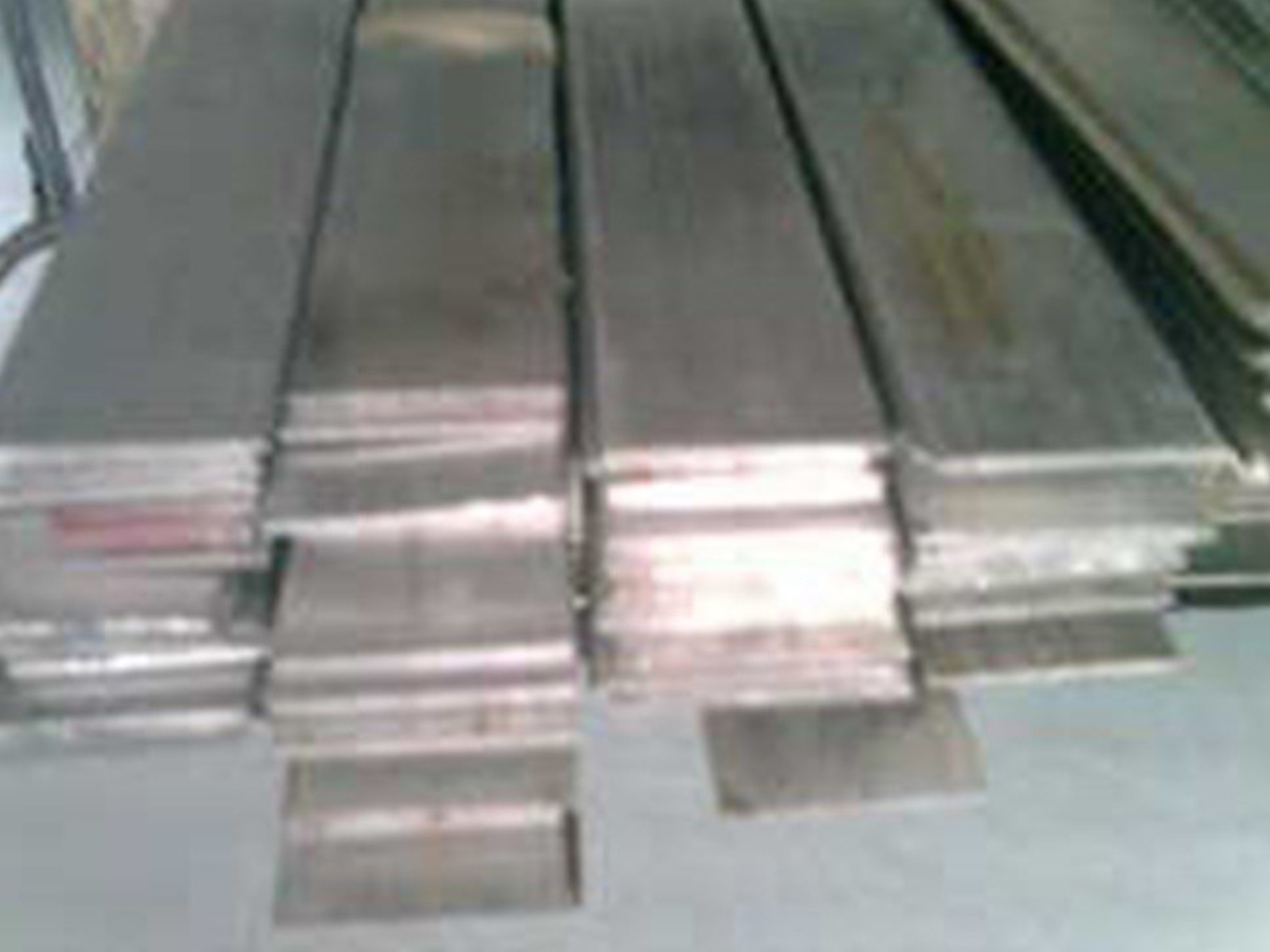

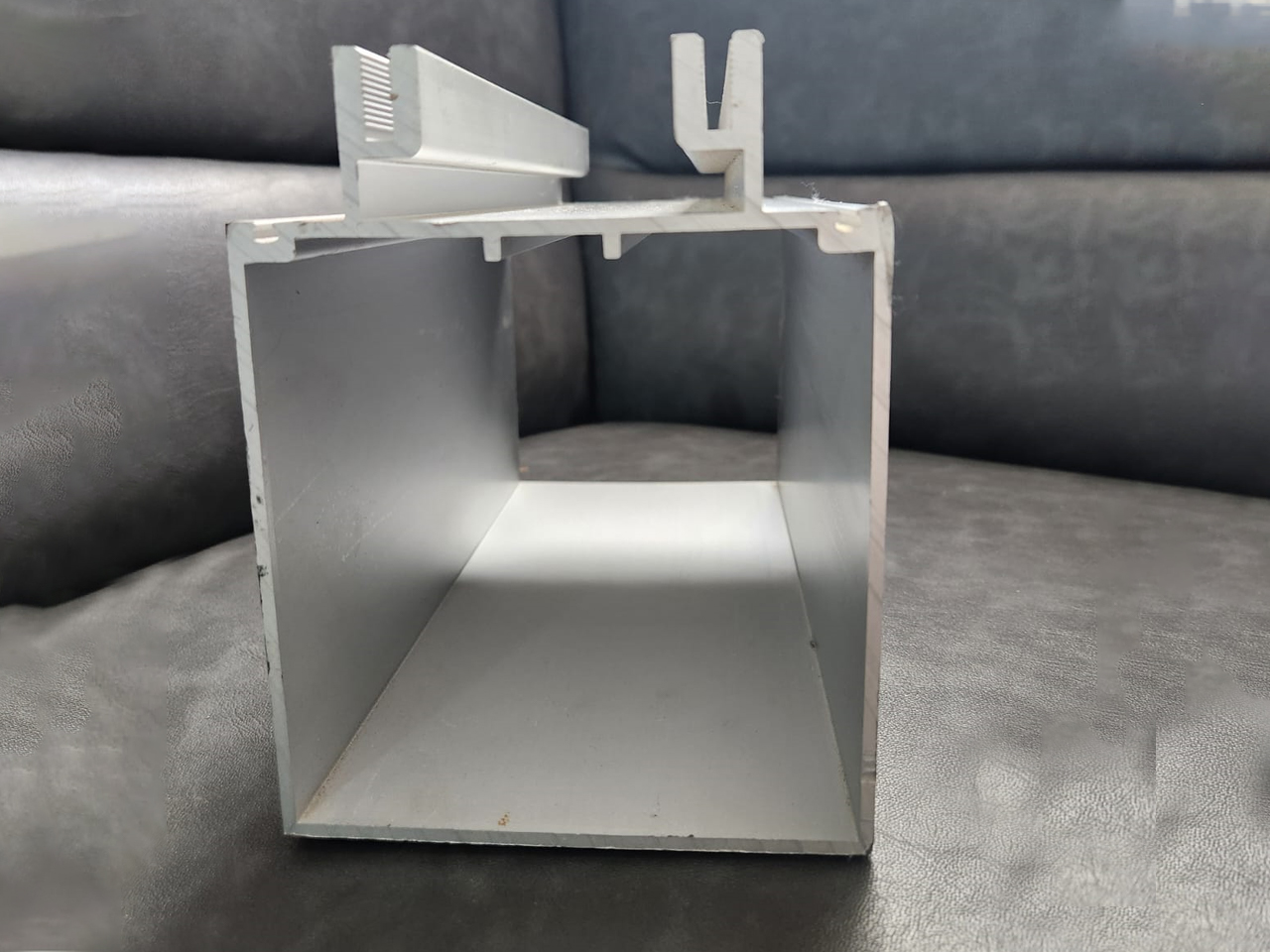

Extrusion is defined as the process of shaping a material (for example, aluminium), first by heating the material to make it flow, and then pouring it through a shaped opening in a tooling die.

The aluminum extrusion process has a relatively low energy footprint (approximately half of ordinary steel), making it a cost-effective, environmentally-friendly choice. Finally, with its high strength-to-weight ratio, aluminium extrusions for sale are ideal for many industrial and domestic applications.

Why Use Aluminium Extrusion?

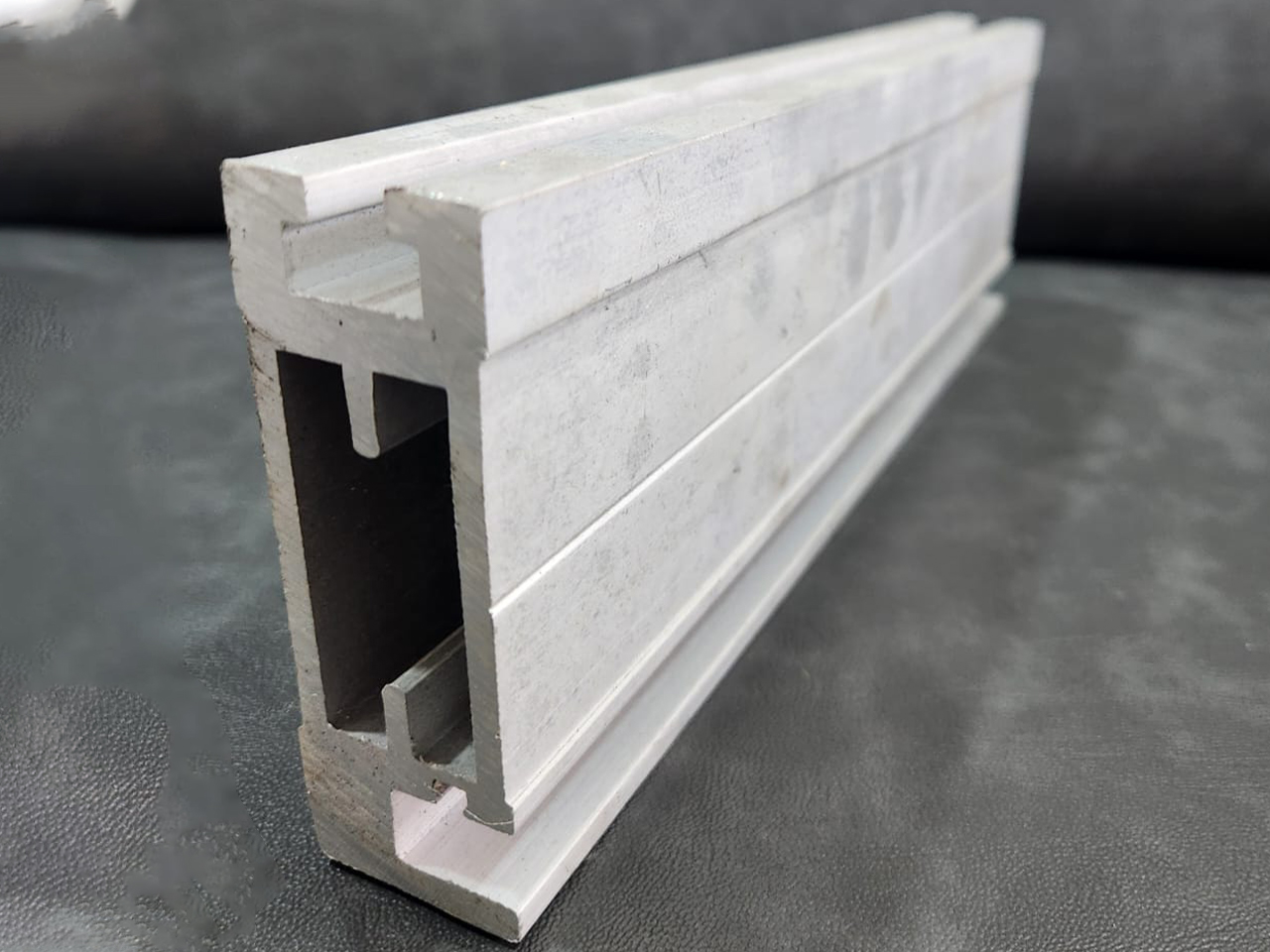

Aluminium is a fascinating material with characteristics that make it especially useful whenever low weight, corrosion-resistance, strength, appearance or thermal or electrical conductivity are important. Extrusion gives it whatever cross-section is desired, which can incorporate a host of useful features. Tee-slots for holding nuts captive are one example, stiffening ribs another. Another point in favour of extrusion is cost. Extrusion dies are far less costly than those for moulding or casting, and can be produced in much less time. In addition, the process itself is relatively inexpensive to operation.