COLLABORATIVE Vision for

Progress & PROSPERITY

At Kesari, we are more than just a manufacturer – we are pioneers in aluminium extrusion industry

Our Products

Your Reliable Aluminum Products Manufacturer In India

If you think about metal fabrications as much as we do, you’ll spot them everywhere. Take a closer look and you’ll see many were built using aluminum extrusion. It is really the most extraordinarily versatile material, and that’s why we like working with it. If you’re wondering whether extruded aluminum might be a good choice for your next project, talk to us.

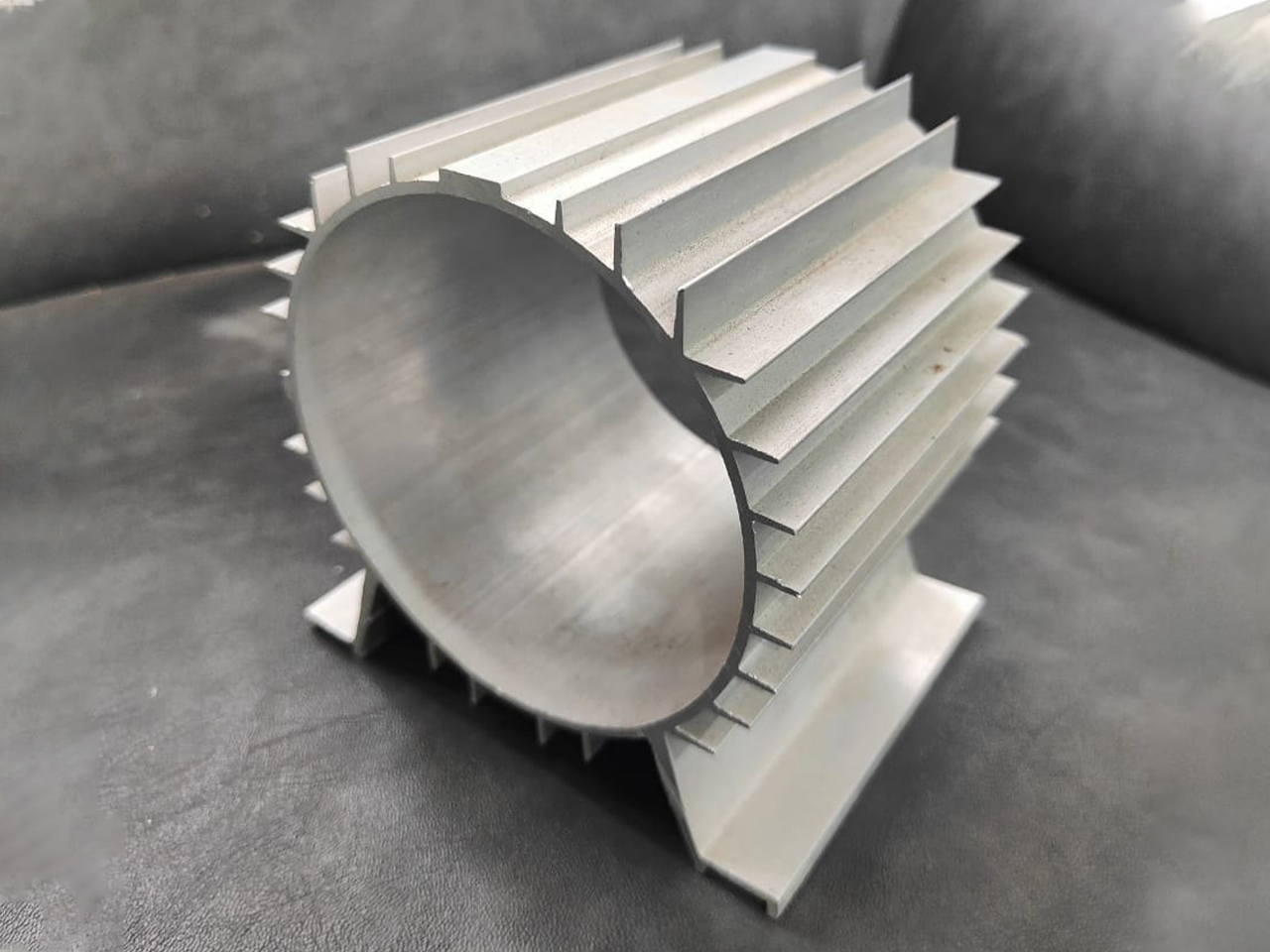

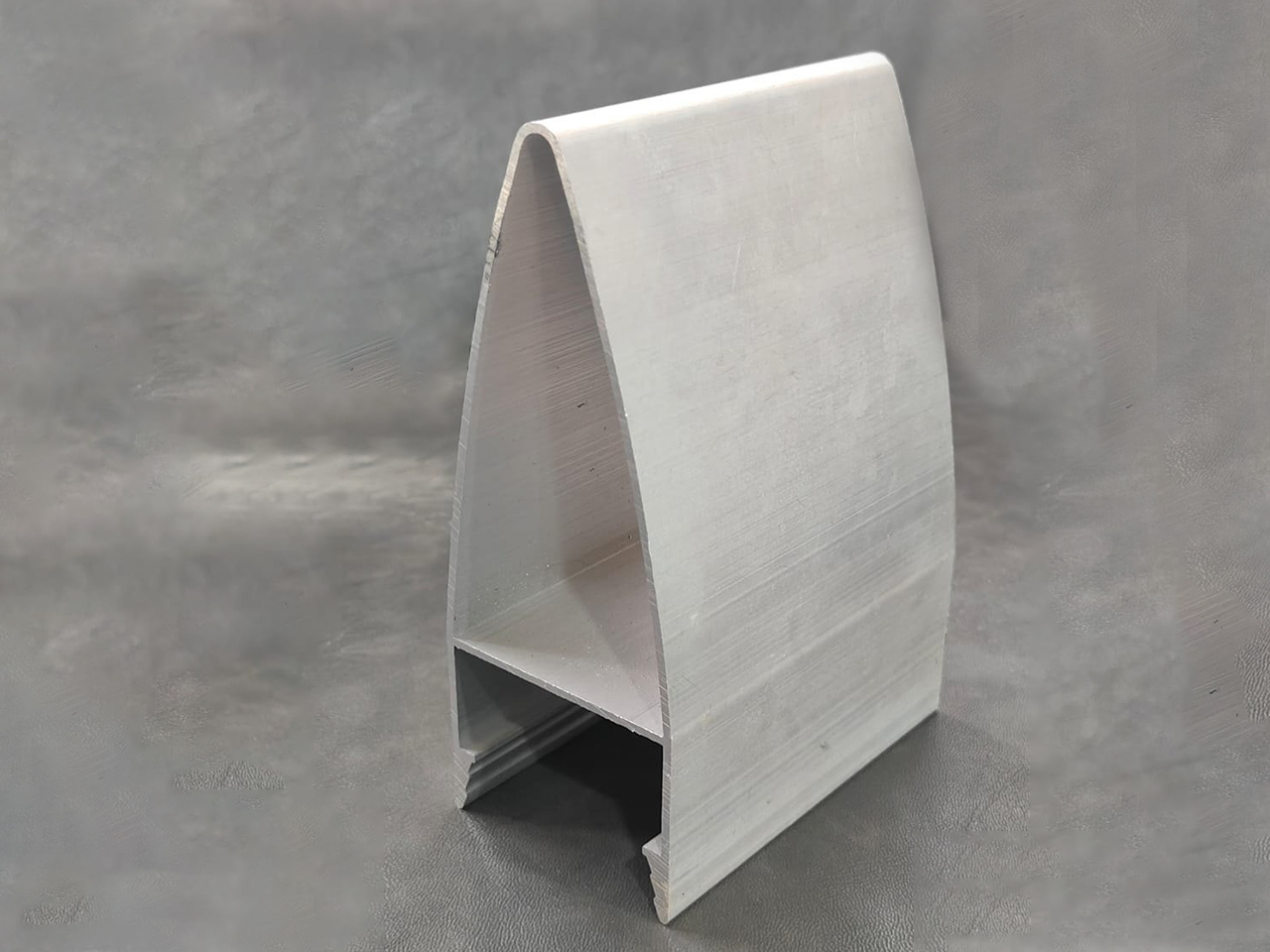

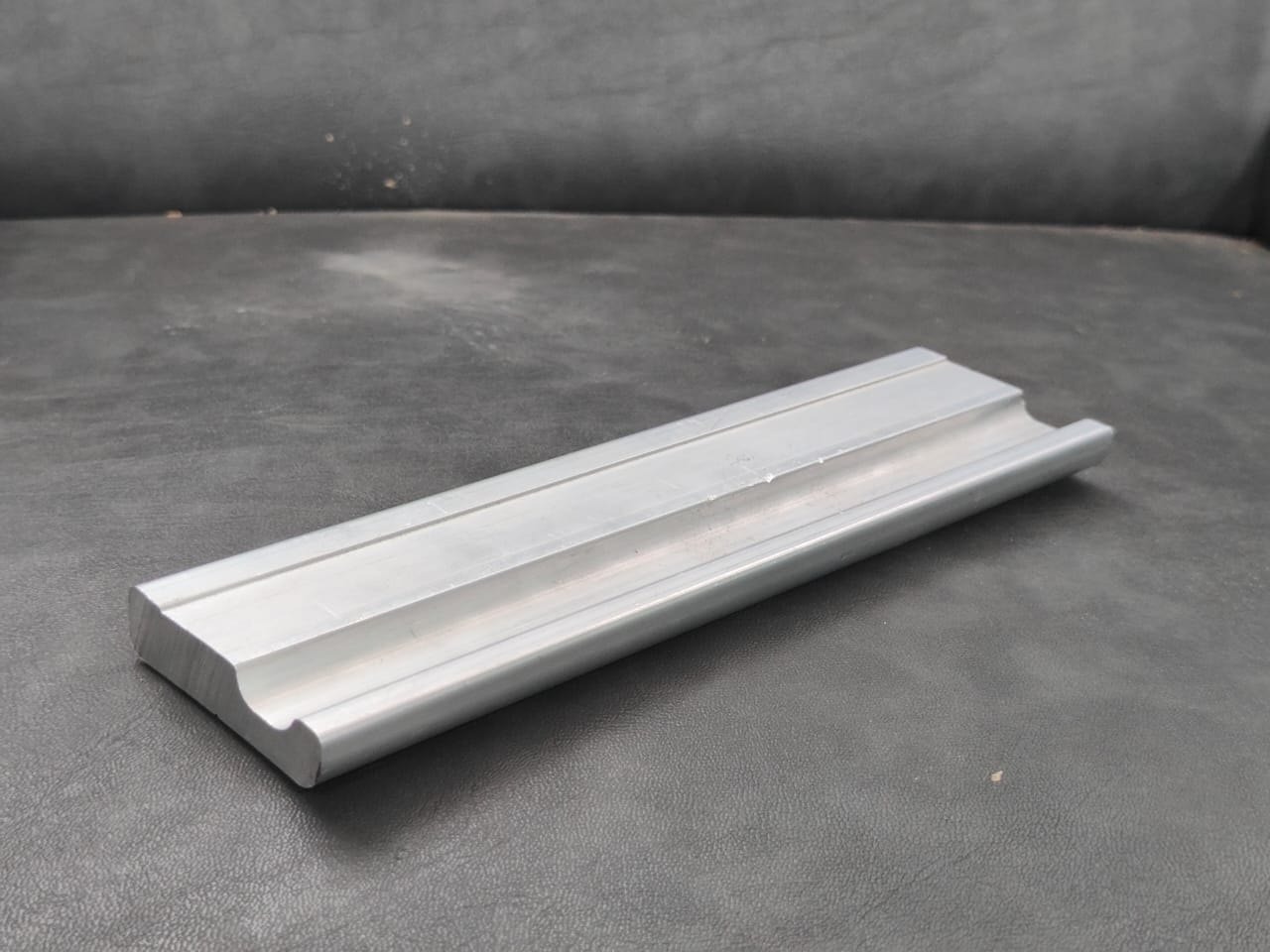

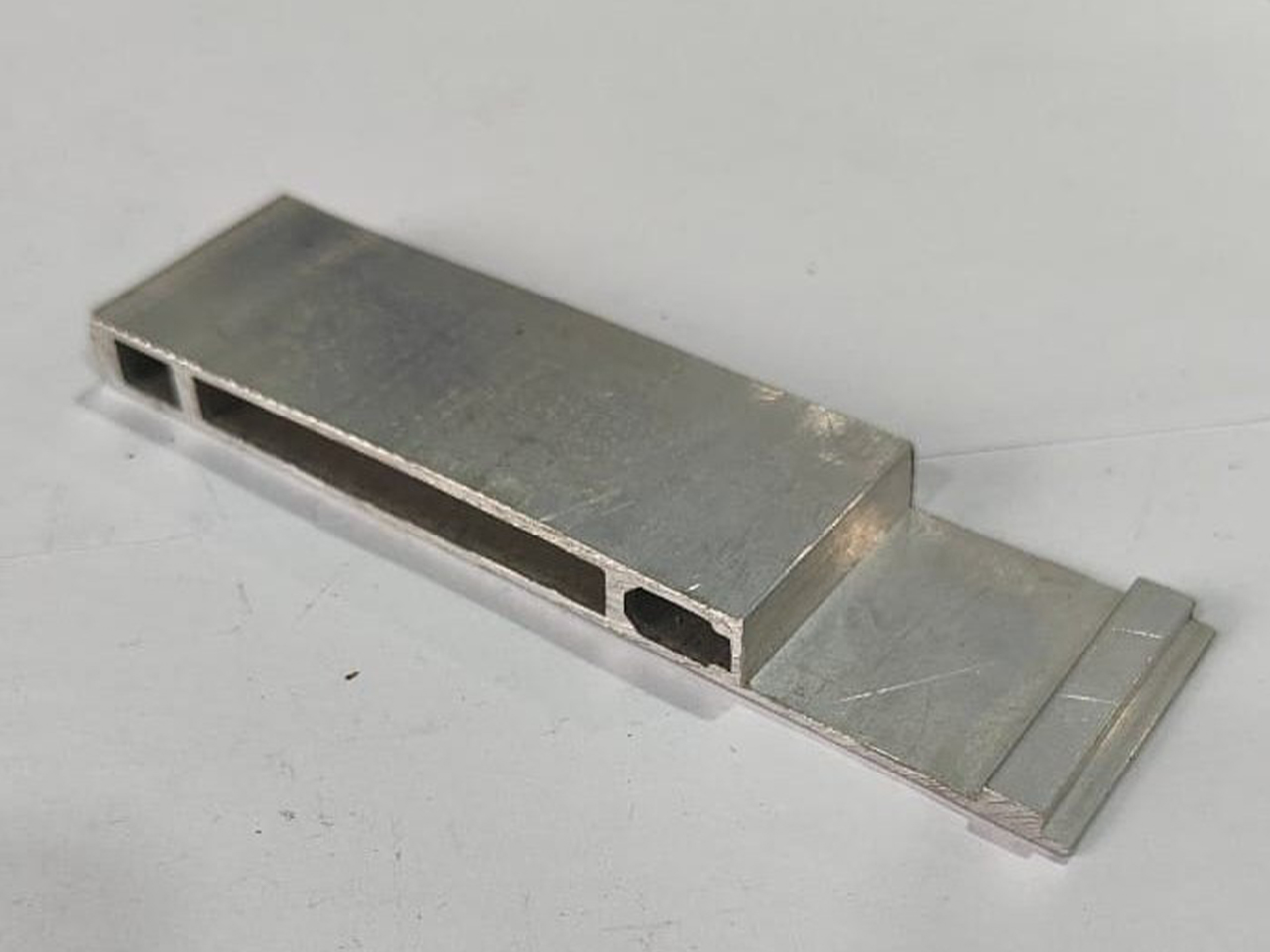

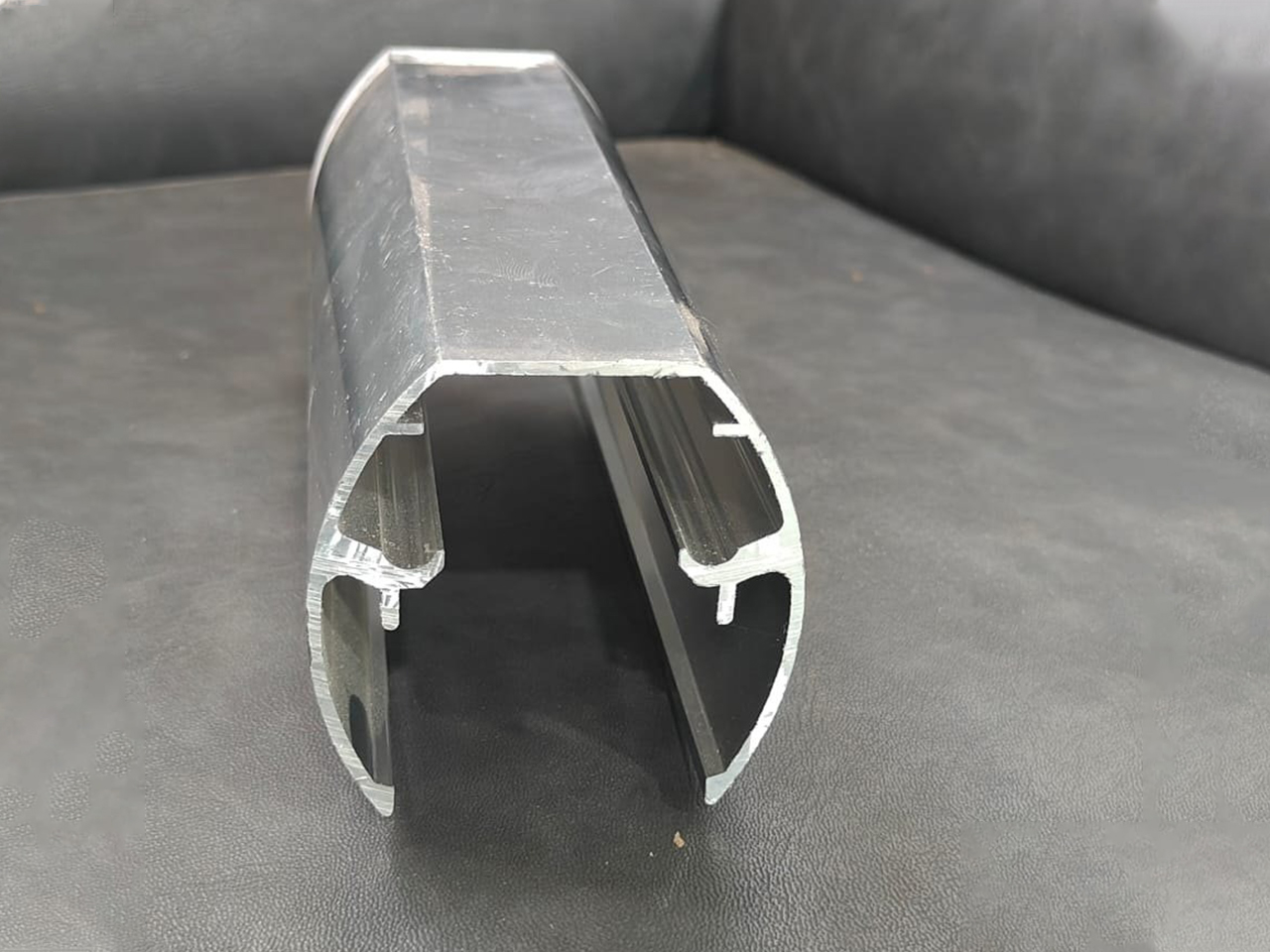

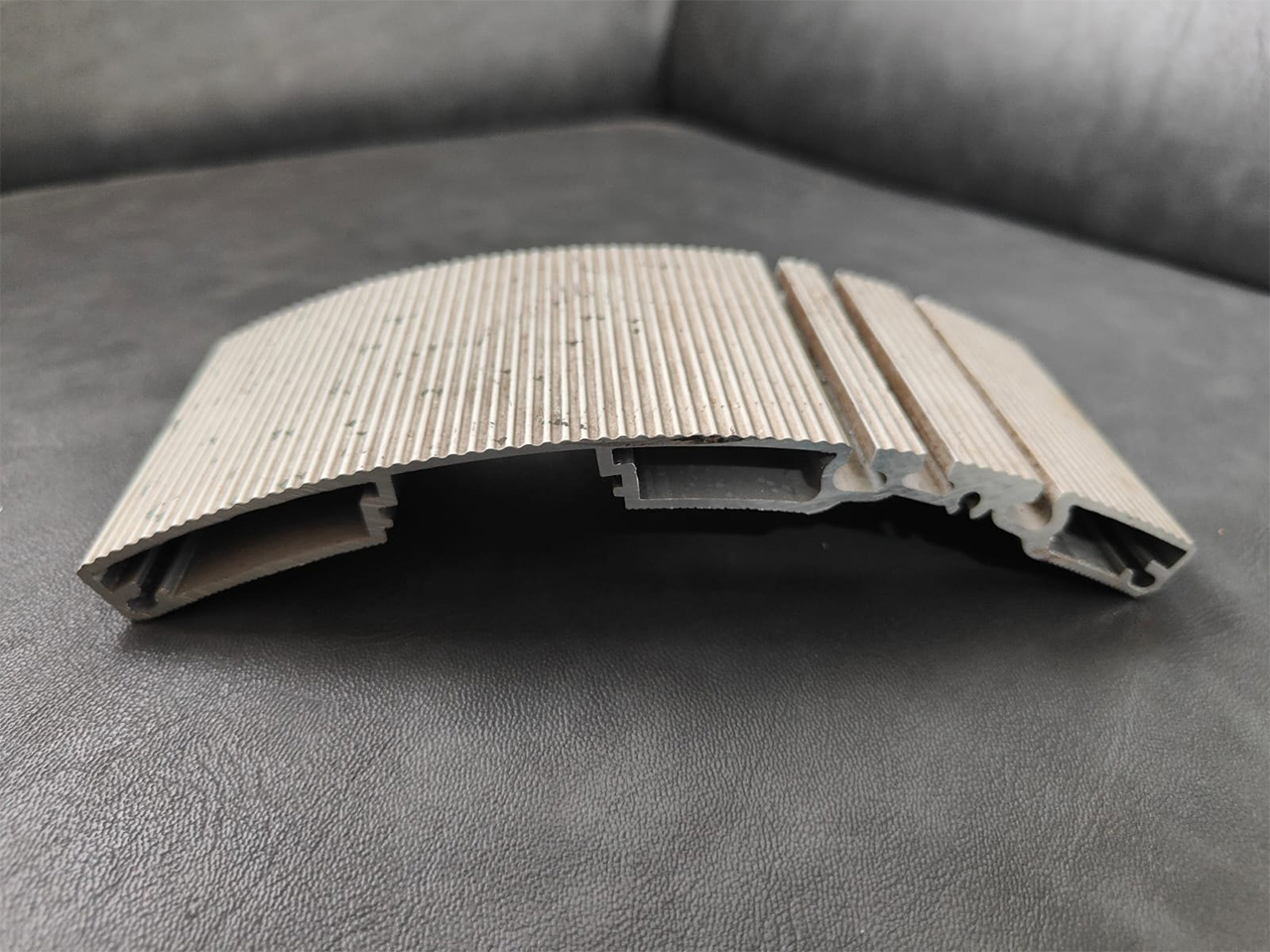

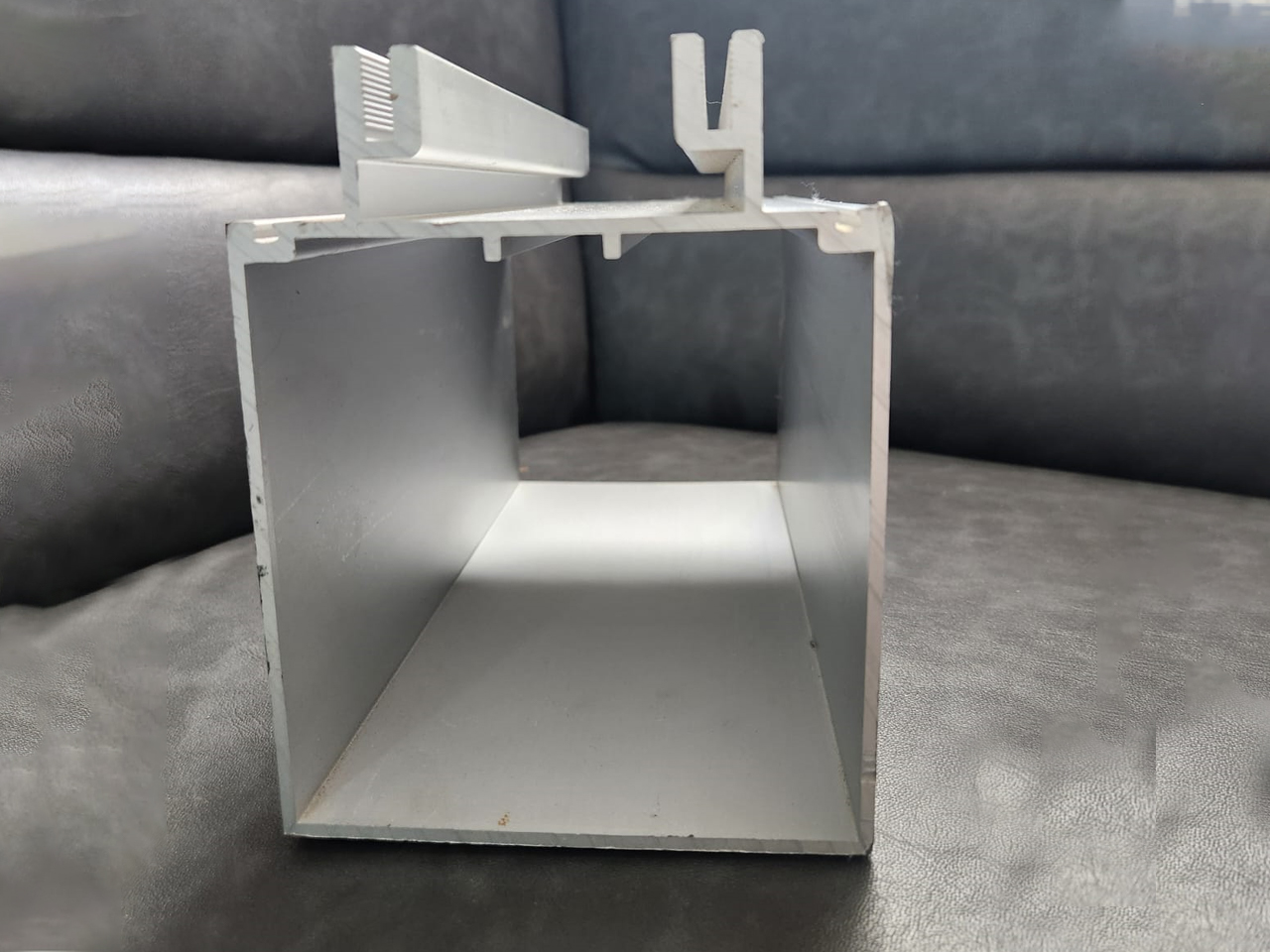

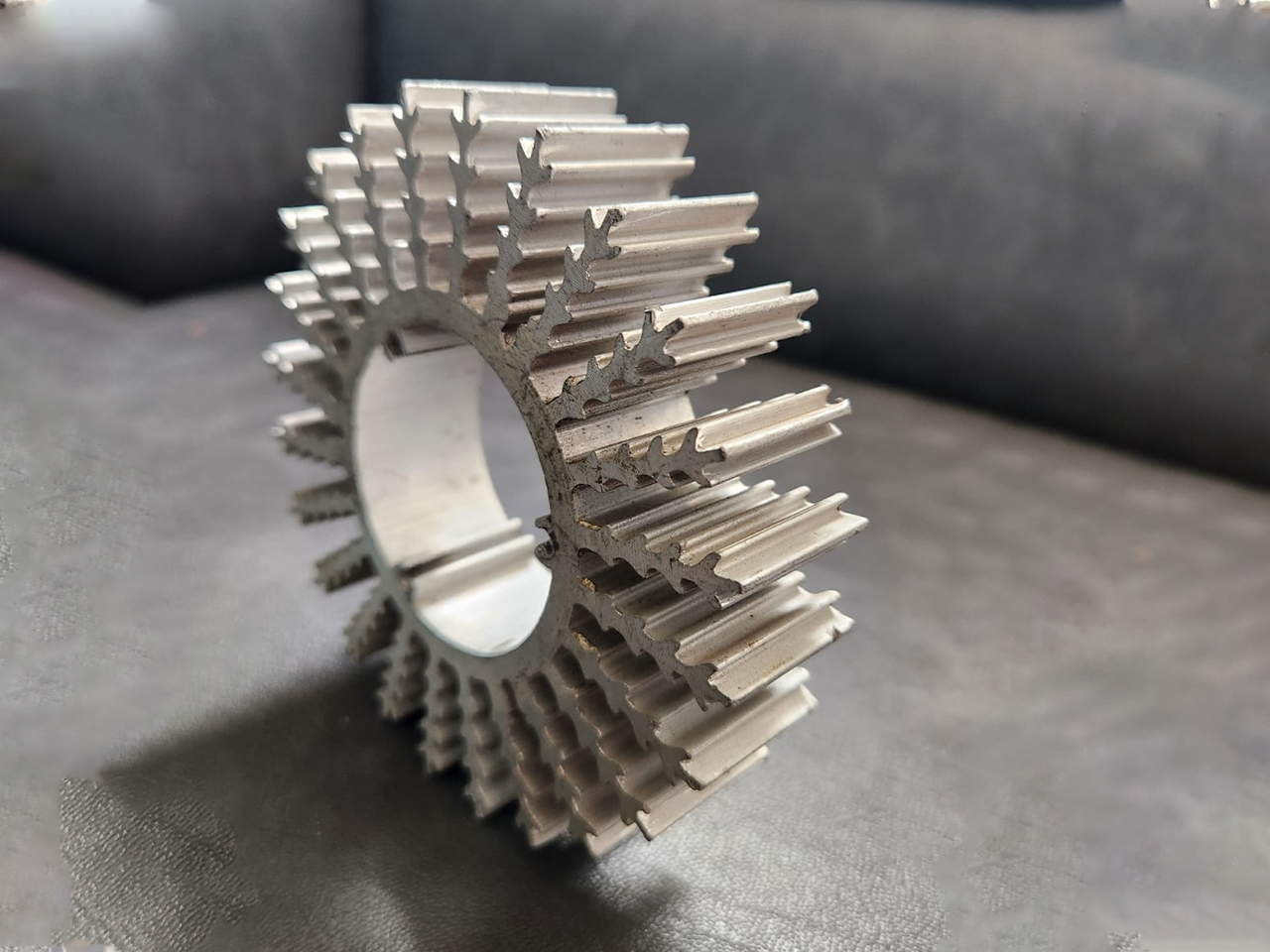

Extrution Profiles

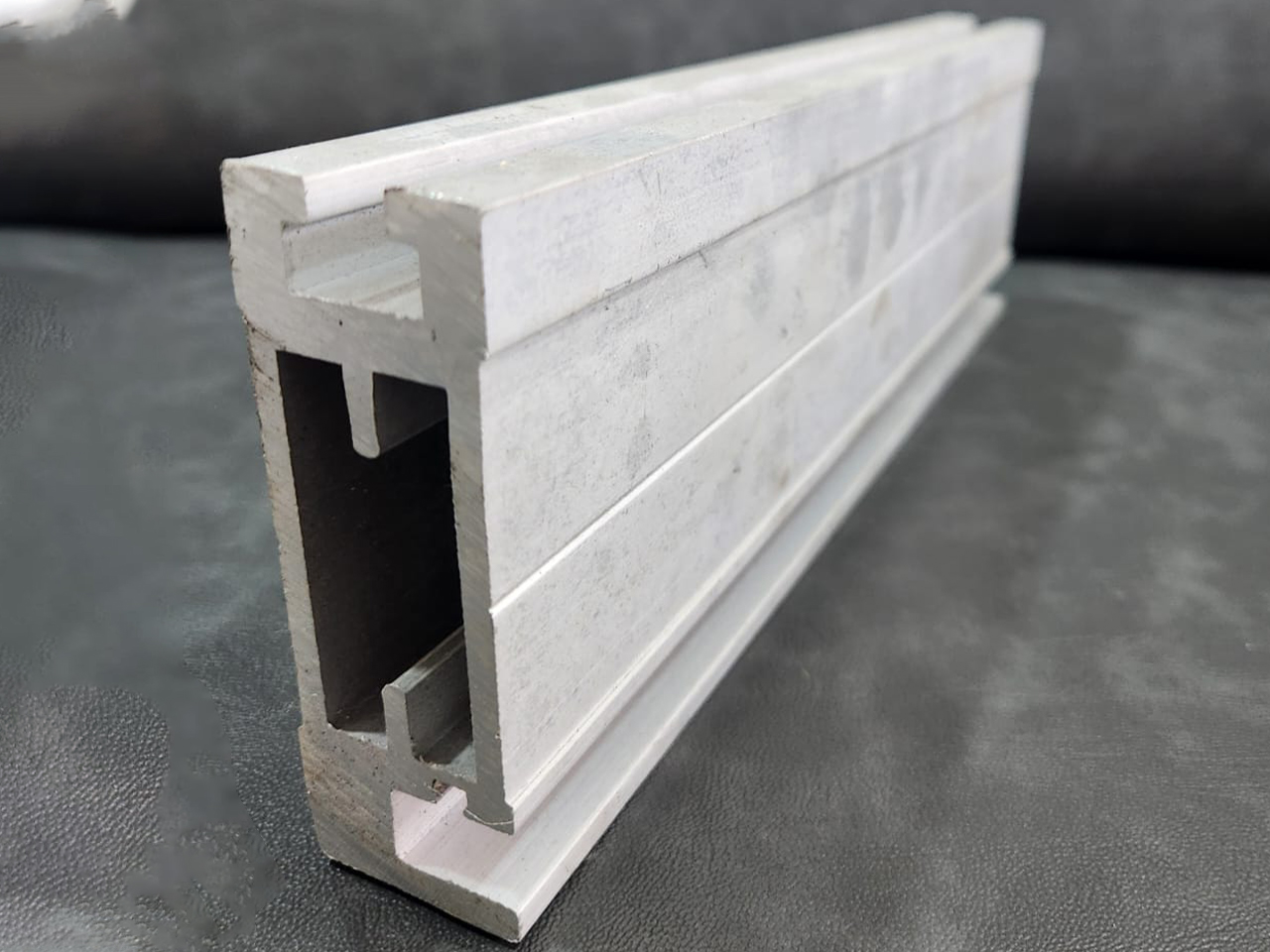

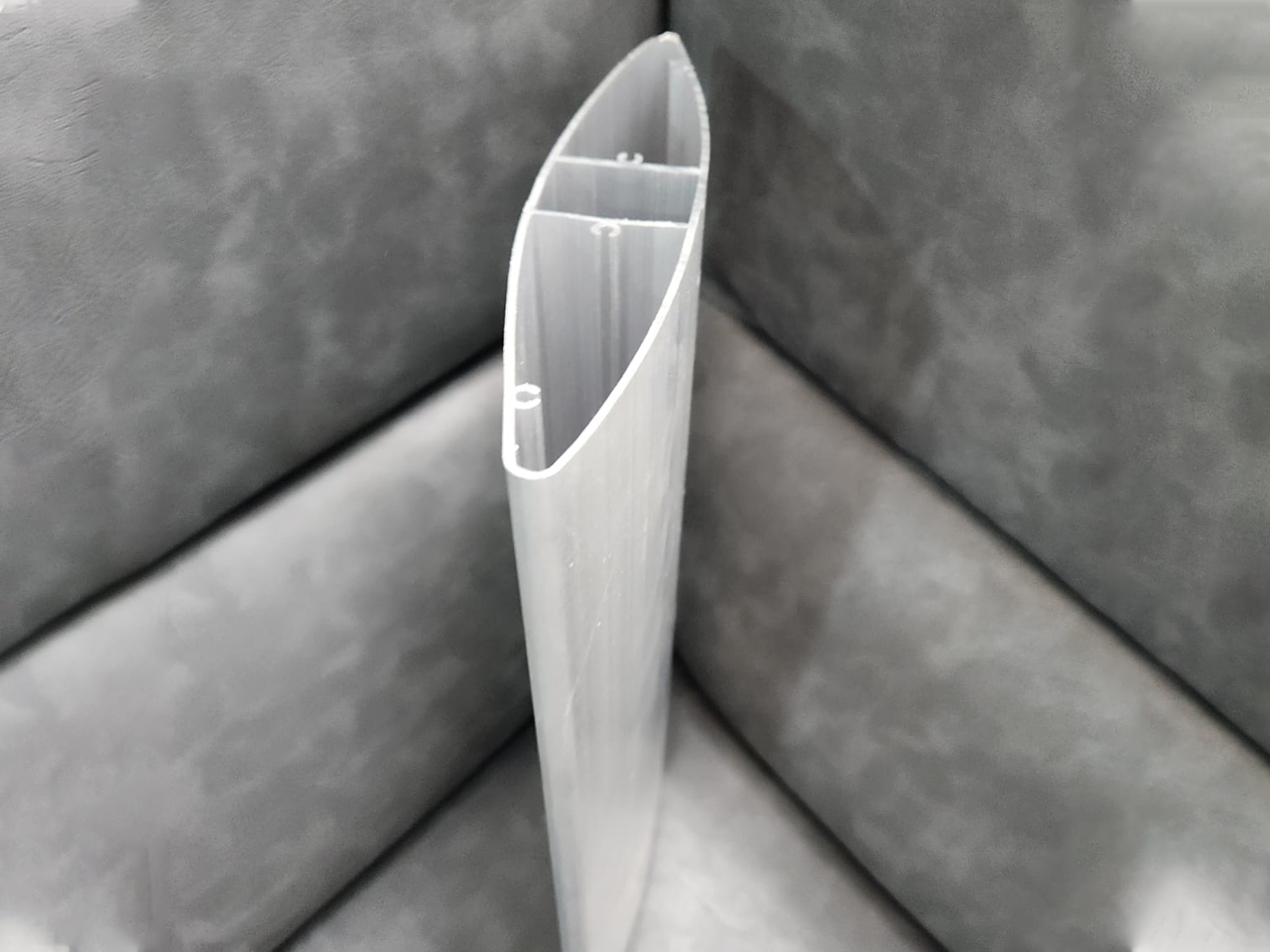

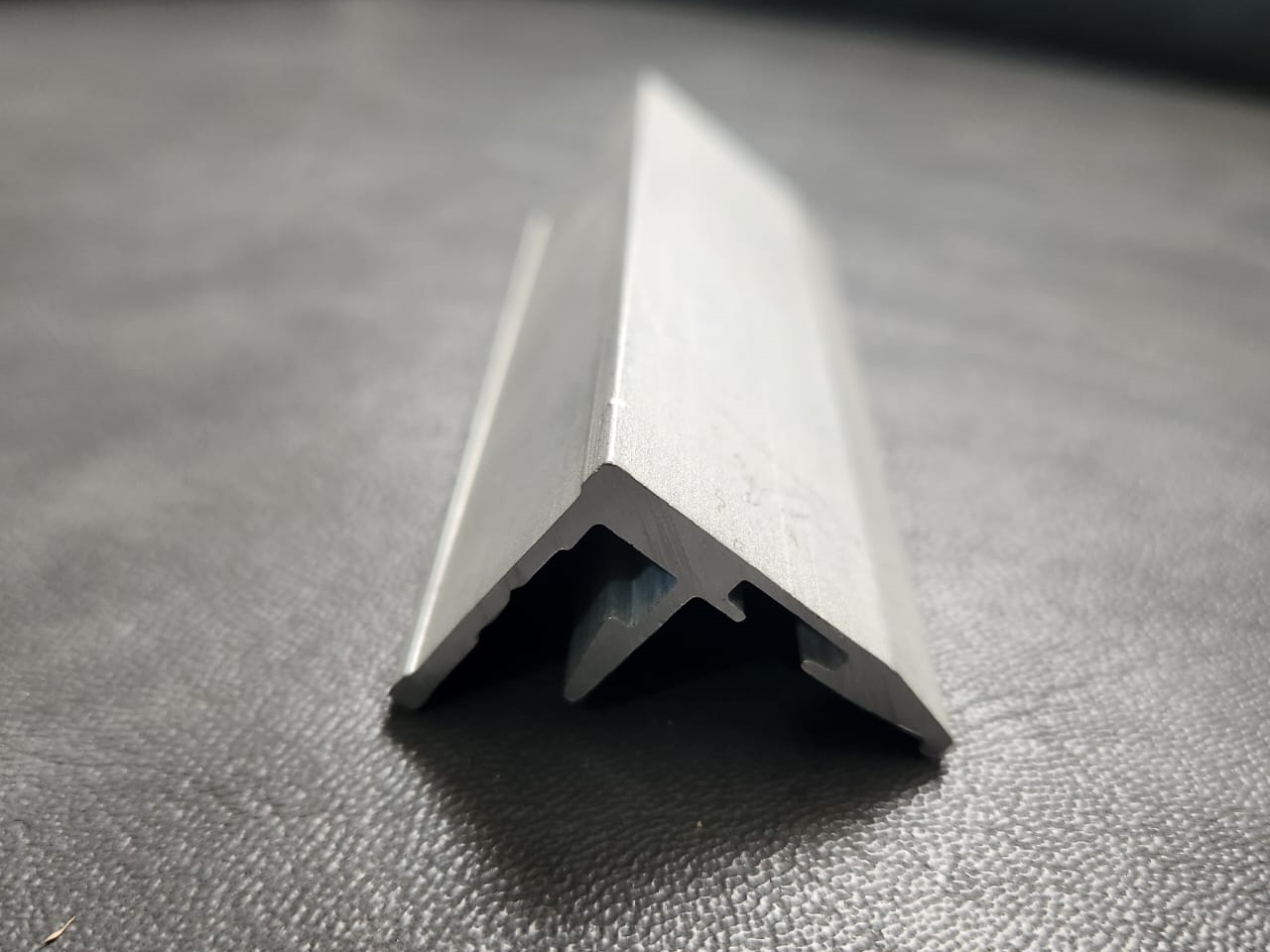

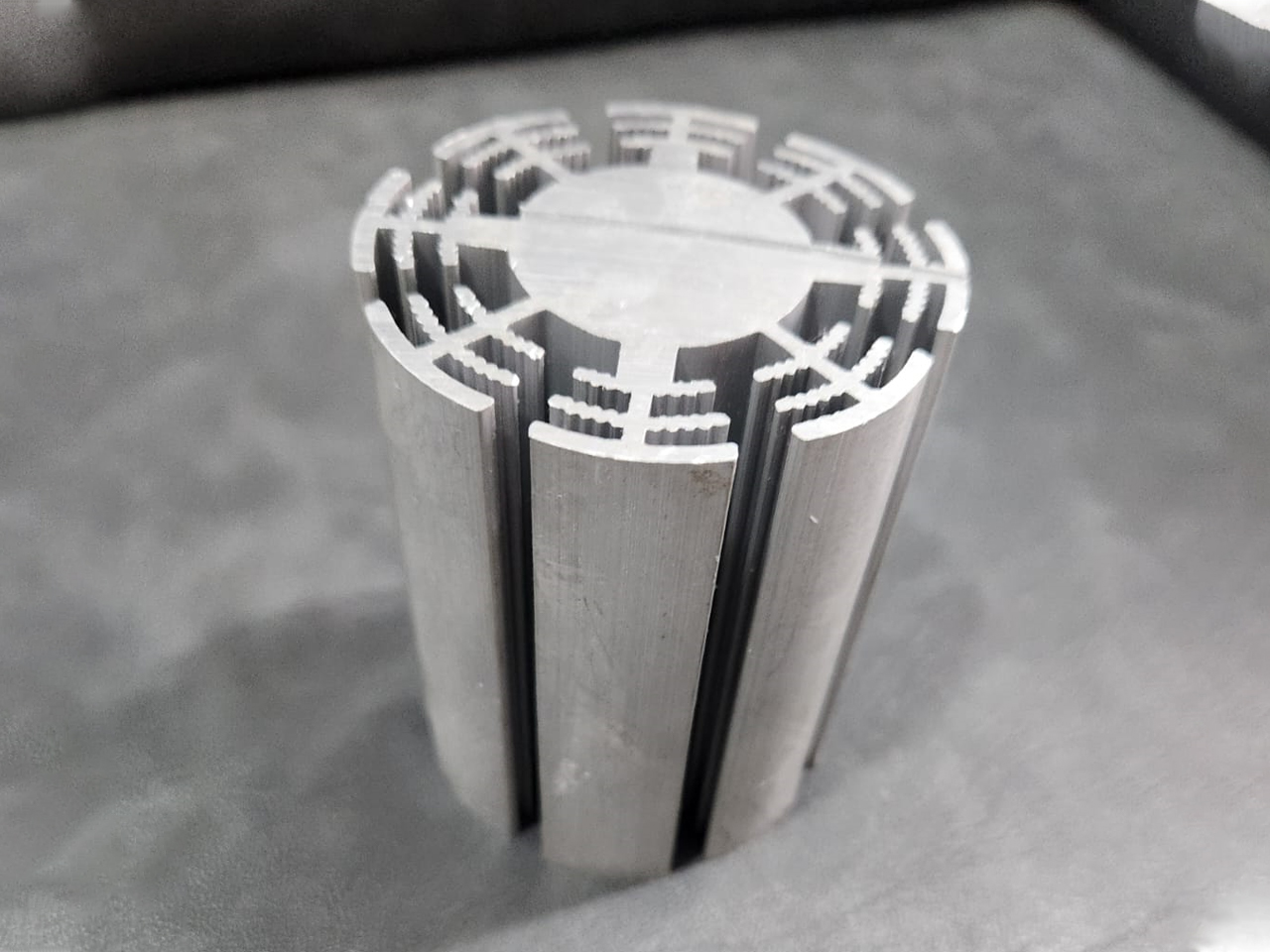

- One of the features of the extrusion process is that it can produce an almost limitless variety of profiles. These are classed as solid, hollow, and semi-hollow.

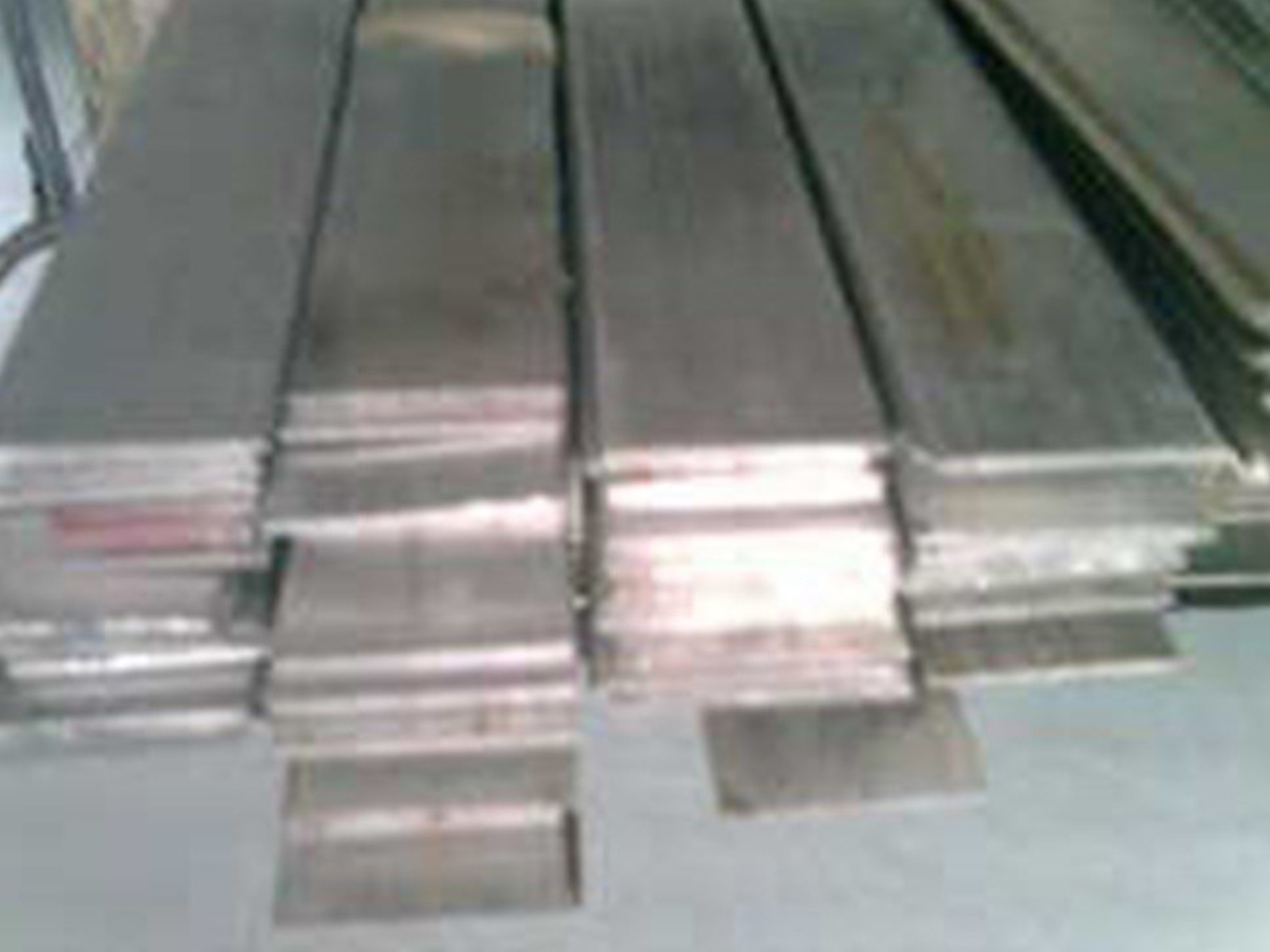

- Square, rectangular, and round bars are the least complicated profiles and are examples of solid extrusions. Hollows are essentially tubes, square, round, rectangular, or any other shape. As the name implies, the profile completely encloses an empty space.

- For semi-hollow extrusion, picture a “C” shape. It’s closed most of the way round with just a small opening in the profile.

- In general, extruded aluminium has great dimensional stability. Semi-hollow section shows the most variability, although still very little, due to a tendency to open out slightly.

- A third electrical example is the use of aluminum extrusion in photovoltaic (solar) panel support structures. These need strength and corrosion-resistance, coupled with low mass, especially in the case of roof-mounted panels.

Why Use Aluminium Extrusion?

“

Aluminium is a fascinating material with characteristics that make it especially useful whenever low weight, corrosion-resistance, strength, appearance or thermal or electrical conductivity are important. Extrusion gives it whatever cross-section is desired, which can incorporate a host of useful features. Tee-slots for holding nuts captive are one example, stiffening ribs another.

Another point in favour of extrusion is cost. Extrusion dies are far less costly than those for moulding or casting, and can be produced in much less time. In addition, the process itself is relatively inexpensive to operate.

Kesari Aluminium